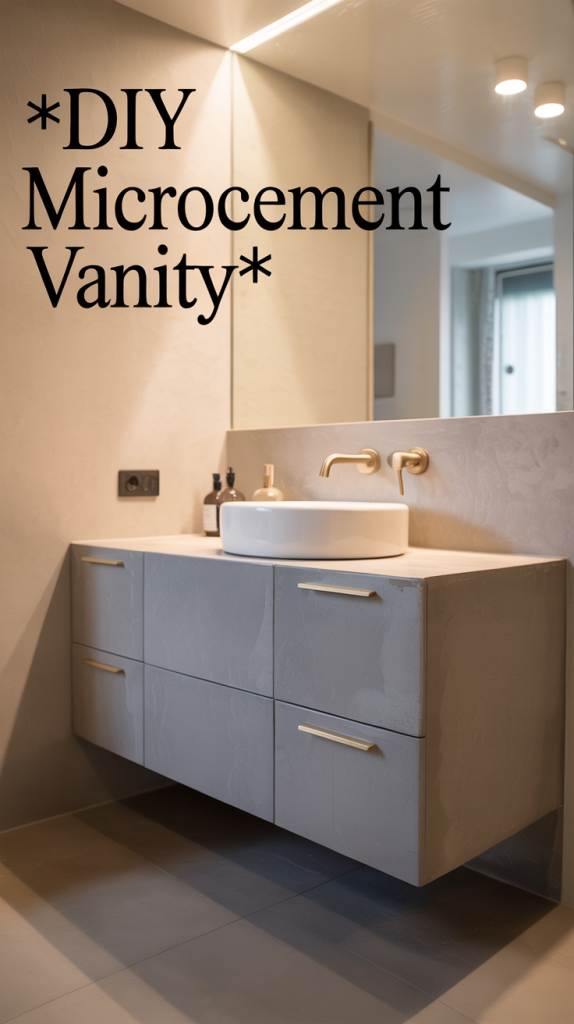

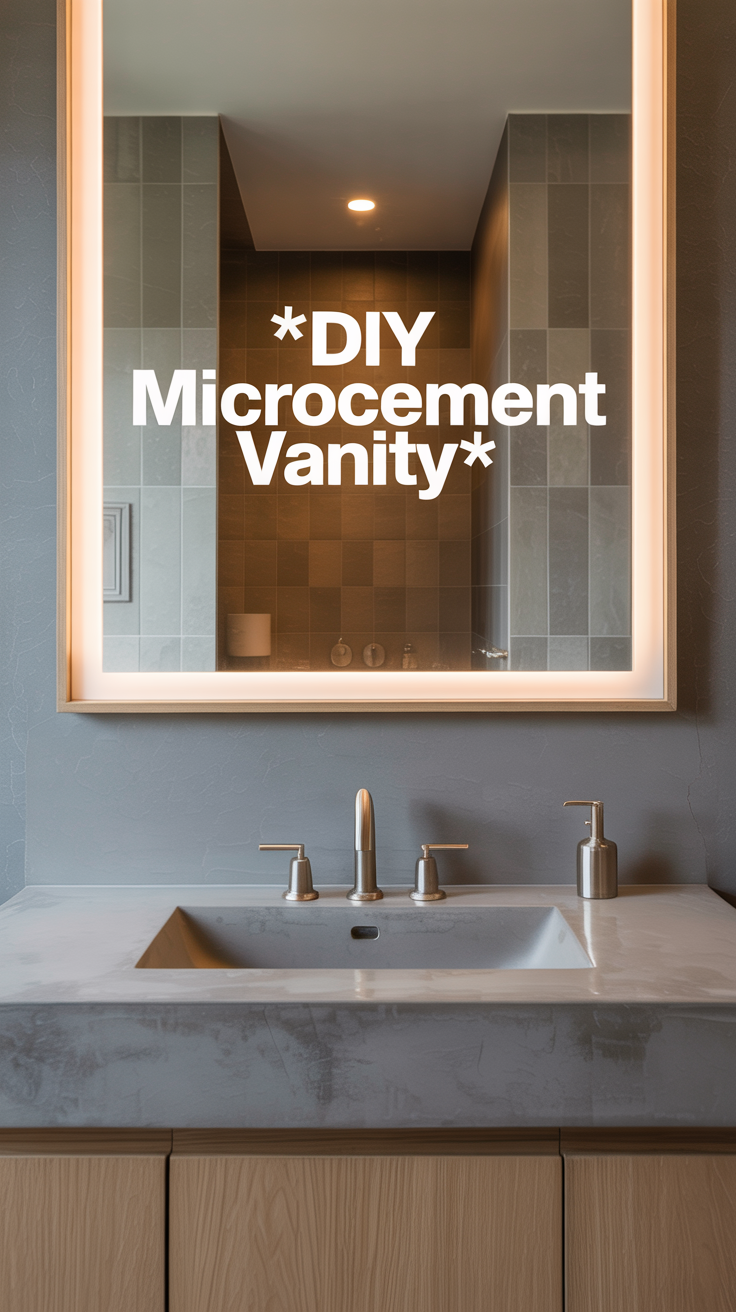

Alright, you all went wild over our post on Microcement Bathrooms so today I want to share our comprehensive guide to building a custom microcement bathroom vanity. Here you will find everything you need to know to create a stunning, one-of-a-kind piece for your bathroom, from initial design to the final finishing touches. We will delve into the unique properties of microcement, explore various design and construction techniques, and provide a detailed, step-by-step guide to help you bring your vision to life. Whether you are a seasoned DIY enthusiast or a novice looking for a rewarding project, this guide will equip you with the knowledge and confidence to create a beautiful and durable microcement vanity that will be the centerpiece of your bathroom for years to come.

The world of interior design is constantly evolving, with new materials and techniques emerging to challenge the status quo. One such material that has been gaining significant traction in recent years is microcement. This versatile and durable material offers a unique aesthetic that is both modern and timeless, making it an ideal choice for a wide range of applications, including bathroom vanities. But what exactly is microcement, and what makes it so special?

What is Microcement? Composition and Properties

Microcement is a polymer-modified cementitious coating that is applied in very thin layers, typically 2-3 millimeters thick. It is composed of a cement base, mixed with water-based resins, additives, and mineral pigments. This unique composition gives microcement its exceptional properties, making it distinct from traditional concrete or plaster. Unlike conventional concrete, which is poured in thick slabs, microcement’s thin application allows for greater flexibility and adhesion to a variety of surfaces without the need for extensive demolition or structural reinforcement. The polymer resins in its composition contribute to its enhanced flexibility, preventing cracking that can often plague traditional cementitious materials. This flexibility is crucial for applications in areas with slight structural movement or thermal expansion, such as bathrooms.

Durability, Water Resistance, and Seamless Finish

One of the most compelling advantages of microcement, especially for bathroom applications, is its remarkable durability and water resistance. Once properly sealed and varnished, microcement creates a non-porous surface that is highly resistant to water penetration, stains, and abrasion. This makes it an excellent choice for wet areas like vanity tops, shower walls, and even floors. The seamless nature of microcement, achieved through its troweled application, eliminates grout lines. This not only contributes to a sleek, modern aesthetic but also significantly reduces maintenance. Grout lines are notorious for collecting dirt, mildew, and grime, making cleaning a constant chore. With microcement, cleaning becomes a simple wipe-down, ensuring a hygienic and pristine bathroom environment .

Furthermore, microcement boasts impressive compressive strength and adhesion, allowing it to be applied over existing surfaces such as tiles, plasterboard, concrete, and even MDF, provided the substrate is stable and properly prepared. This eliminates the need for costly and time-consuming demolition, making it a more sustainable and DIY-friendly option. Its resistance to UV light also means that its color will not fade over time, maintaining its aesthetic appeal for years to come. The inherent strength of the material, combined with its protective sealers, ensures that a microcement vanity can withstand the rigors of daily use in a busy bathroom, resisting chips, scratches, and general wear and tear far better than many conventional materials.

Versatility in Application and Aesthetic Appeal

Beyond its functional benefits, microcement offers unparalleled versatility in terms of design and aesthetic. It can be tinted with a wide array of mineral pigments, allowing for an extensive palette of colors to match any design scheme. The application technique itself lends to unique textures and finishes, from smooth and polished to more rustic and textured, depending on the trowel work and sanding. This artistic flexibility means that no two microcement surfaces are exactly alike, giving each project a truly custom and handcrafted feel. The seamless, continuous surface creates an illusion of space and fluidity, which is particularly beneficial in smaller bathrooms, making them appear larger and more open. Its minimalist aesthetic aligns perfectly with contemporary design trends such as Modern Mediterranean, industrial, and Scandinavian styles, offering a sophisticated backdrop that complements various fixtures and fittings.

Comparison with Traditional Materials

When compared to traditional bathroom vanity materials, microcement stands out. Ceramic or porcelain tiles, while durable and water-resistant, come with grout lines that require constant cleaning and can detract from a seamless look. Natural stone, such as granite or marble, offers luxury but is often prohibitively expensive, heavy, and requires specialized installation and sealing. Laminate countertops are budget-friendly but lack the durability and high-end finish of microcement, being susceptible to water damage and delamination over time. Solid surface materials like Corian offer seamlessness but can be prone to scratching and may not provide the same organic, tactile feel as microcement. Wood, while warm and inviting, demands rigorous waterproofing and maintenance in a bathroom setting. Microcement, therefore, presents a compelling alternative, offering the aesthetic appeal of natural stone, the seamlessness of solid surfaces, and the durability of tiles, all within a more budget-friendly and DIY-accessible framework . Its ability to be applied thinly over existing structures also makes it an environmentally conscious choice, reducing waste associated with demolition and new material production. This blend of aesthetic flexibility, robust performance, and cost-effectiveness positions microcement as a superior choice for the discerning DIYer looking to create a high-impact, low-maintenance bathroom vanity.

3. Planning Your Dream Vanity: Design, Measurements, and Structural Considerations

Before diving into the construction phase, meticulous planning is paramount. A well-thought-out design, accurate measurements, and a clear understanding of structural requirements will not only ensure the success of your DIY microcement vanity project but also prevent costly mistakes and frustrations down the line. This section will guide you through the essential planning steps, from conceptualizing your aesthetic vision to ensuring the structural integrity of your custom piece.

Conceptualizing Your Design: Modern Mediterranean, Minimalist, Industrial

The beauty of a custom-built vanity lies in its ability to perfectly align with your personal style and the overall aesthetic of your bathroom. The inspiration for this project, a ‘Modern Mediterranean’ style vanity, speaks to a clean, minimalist, and organic aesthetic. However, microcement is incredibly versatile and can adapt to various design themes. Consider the following:

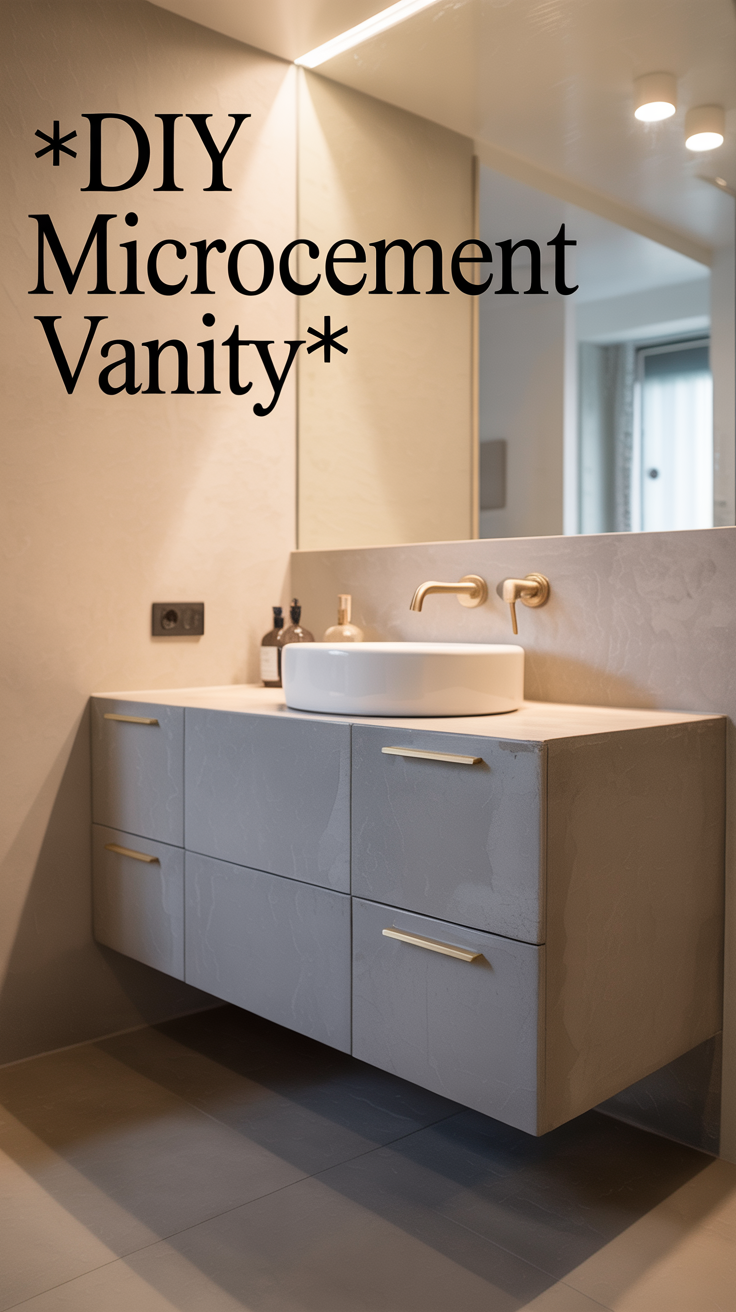

•Modern Mediterranean: Characterized by clean lines, natural textures, earthy tones, and a sense of calm. Microcement’s smooth, often matte finish, and neutral color palette (greys, whites, natural earth tones) are perfectly suited for this style. Incorporate elements like rounded edges, as seen in the inspiration, to soften the look and add a touch of organic elegance.

•Minimalist: Emphasizes simplicity, functionality, and uncluttered spaces. A microcement vanity, with its seamless surface and understated presence, is a natural fit for minimalist design. Focus on clean lines, a monochromatic color scheme, and integrated sinks to maintain a sleek profile.

•Industrial: Draws inspiration from factories and urban lofts, featuring raw materials like concrete, metal, and exposed brick. Microcement, with its concrete-like appearance, can be left with a slightly more textured finish to enhance this aesthetic. Pair it with black metal fixtures and exposed piping for a truly industrial feel.

Before you even pick up a tool, spend time gathering inspiration. Look at images online, in magazines, or even in local showrooms. Create a mood board to visualize your desired outcome, including colors, textures, and fixtures. This initial design phase is crucial for defining the scope and style of your project.

Taking Precise Measurements: Width, Height, Depth, Sink Placement

Accurate measurements are the cornerstone of any successful DIY project, especially when building a custom vanity. Unlike off-the-shelf units, your custom vanity will fit your space perfectly, but only if your measurements are precise.

Start by measuring the available space in your bathroom. Consider the following dimensions:

•Width: Measure the wall space where the vanity will be located. If it’s an alcove, measure from wall to wall. If it’s a freestanding unit against one wall, determine your desired width, keeping in mind clearances for doors, showers, and toilets. The inspiration project utilized the maximum possible width (55 inches) to accommodate two sinks, which is a common desire for double vanities .

•Height: Standard vanity height is typically around 32-36 inches from the floor to the top of the countertop. Consider the height of your chosen sink (vessel, undermount, integrated) and the comfort of the primary users. The inspiration vanity was around 35 inches high .

•Depth: Standard vanity depth is usually 21-24 inches from front to back. Ensure there’s enough clearance for plumbing behind the vanity and comfortable reach to the faucet. Also, account for any overhang your chosen countertop material might have.

•Sink Placement: If you’re planning for one or two sinks, mark their approximate centerlines on your design. This will be critical for framing and plumbing rough-ins. For integrated sinks, as seen in the inspiration, the fabricator will need precise dimensions and placement details .

Remember to account for the thickness of your materials – the 2×4 framing, the 1/2-inch cement board, and the microcement layers. These seemingly small dimensions can add up and impact the final fit of your vanity. Always measure twice, or even thrice, before making any cuts.

Structural Support is Key: Reinforcing Walls, Stud Placement, Weight Distribution

A bathroom vanity, especially one with a solid countertop and potentially heavy sinks, requires robust structural support. The original article highlights the importance of reinforcing the right wall with blocking to support the weight of the countertop . This is a critical step that should not be overlooked.

•Locate Wall Studs: Before any construction begins, use a stud finder to accurately locate and mark the wall studs where your vanity will be attached. Your vanity frame should be securely fastened to these studs. If your desired vanity placement doesn’t align perfectly with existing studs, you may need to add horizontal blocking between studs to provide adequate anchoring points.

•Reinforce Walls: For heavy countertops like quartz or concrete, or if you plan to hang the vanity (though this project describes a built-in), reinforcing the wall with additional blocking or plywood sheathing behind the drywall is highly recommended. This distributes the weight more effectively and prevents the vanity from pulling away from the wall over time.

•Floor Anchoring: For built-in vanities, securing the base frame to the floor provides additional stability. The inspiration project mentions the left wall being secured into the floor for stability . Use appropriate fasteners for your subfloor type.

•Weight Distribution: Design your frame to distribute the weight of the countertop and sinks evenly across the structure. Vertical supports should be directly beneath areas of concentrated weight, such as under the sink basins. The 2×4 and 2×8 lumber used in the inspiration project provides a sturdy base for this purpose .

Ignoring structural support can lead to sagging, instability, and potential damage to your plumbing or bathroom finishes. It’s always better to over-engineer for stability in a bathroom environment.

Customization Options: Partial Walls, Integrated Shelving, Rounded Edges

The beauty of DIY is the freedom to customize. The inspiration project showcases several clever customization options that elevate the vanity from a simple box to a bespoke piece:

•Partial Walls: Adding a partial wall, as seen on the left side of the inspiration vanity, creates a sense of privacy and makes the unit feel more integrated and built-in . This can also serve as a natural divider in a larger bathroom or provide a discreet space for toiletries.

•Integrated Shelving: The addition of a shelf near the bottom, constructed with 2x4s and pocket holes, adds practical storage and visual interest . Consider open shelving for towels or decorative items, or enclosed shelving for less attractive necessities.

•Rounded Edges: The rounded edge of the partial wall in the inspiration project is a sophisticated detail that softens the overall aesthetic. This was achieved by adding a support block, tracing a round object, and then shaping the wood with a hand planer and orbital sander . This technique can be adapted for other corners or edges of your vanity to create a unique, organic feel. When applying microcement, these rounded edges will translate into a smooth, continuous curve, enhancing the seamless look.

Think about how these elements can enhance both the functionality and the visual appeal of your vanity. Sketch out different configurations and consider how they will interact with the rest of your bathroom design. These custom touches are what will truly make the vanity

4. Materials and Tools: Gathering Your Arsenal

A successful DIY project is as much about having the right materials and tools as it is about skill and planning. For your custom microcement vanity, you’ll need a combination of standard carpentry supplies, specialized microcement products, and a few essential tools. Investing in quality materials and tools will not only make the process smoother but also contribute to a more durable and professional-looking final product. Below is a comprehensive list, drawing from the inspiration project and our additional research, to help you prepare.

Lumber: The Structural Backbone

•2x4x8’s: These are the workhorses for framing the vanity’s skeleton. You’ll need several, depending on the size and complexity of your design. They provide the primary structural support for the vanity. The original project used these extensively for the main frame .

•2x8x8’ (optional): Used in the inspiration project along the front and left side to achieve a desired height and robust apron. Alternatively, you can stack multiple 2x4s to reach the same height, offering flexibility based on material availability and preference .

Substrate: The Foundation for Microcement

•1/2″ Cement Board: This is crucial for creating a stable, moisture-resistant surface for microcement application. It’s more durable and water-resistant than drywall in a bathroom environment. You’ll use it for the sides, shelves, and any other surfaces that will receive microcement .

•Joint Tape: Specifically designed for cement board seams, this tape helps reinforce joints and prevents cracking in the microcement layer above. It’s applied before waterproofing .

Waterproofing: Essential for Bathroom Longevity

•Waterproofing Membrane (e.g., Elastoshield, RedGard): A rubbery, liquid-applied coating that dries to a hard, waterproof finish. It’s applied over the cement board and any wood surfaces that will be exposed to moisture, providing a critical barrier against water penetration. This step is non-negotiable for a durable bathroom vanity [1, 4].

•Primer: While often included in microcement systems, a dedicated primer might be needed for specific substrates or to enhance adhesion before applying the waterproofing membrane or the microcement base coat .

Microcement System: The Star of the Show

•Microcement Base Coat: The initial layer of microcement, providing adhesion and a foundational surface. This is typically mixed with a liquid polymer .

•Microcement (Finish Coat): The decorative layer that provides the final color and texture. Available in various grades for different finishes (e.g., fine for smooth, coarse for textured). The inspiration project used untinted Microtek microcement .

•Pigment: If you desire a colored microcement, pigments are added to the mix. Ensure they are compatible with your chosen microcement system .

•Sealer: Applied after the microcement has cured, the sealer protects the surface from stains and water, and intensifies the color. It’s a vital step for durability and ease of cleaning [1, 2].

•Finishing Varnish: The final protective layer, offering complete water resistance and protection against cleaning products. Available in matte, satin, or glossy finishes, allowing you to customize the final look .

Countertop Options: Beyond the Microcement Surface

While the vanity structure will be microcement, you have choices for the actual countertop surface. The original project opted for a high-end quartz, but budget-friendly DIY alternatives exist [1, 3]:

•Quartz/Natural Stone: If budget allows, a fabricated quartz or natural stone slab offers exceptional durability and a luxurious finish. Consider sourcing remnants for cost savings .

•DIY Concrete: A highly customizable and cohesive option with microcement. This involves pouring and finishing concrete to create a solid, durable surface. This can be done in-situ or as a pre-cast slab .

•Butcher Block: Offers a warm, natural aesthetic. Requires thorough sealing and regular maintenance to withstand bathroom moisture .

•Laminate: The most budget-friendly option, available in many styles. Easy to install but less durable in wet environments if not perfectly sealed .

Essential Tools: Equipping Your Workshop

•Measuring and Marking:

•Tape Measure, Pencil, Carpenter’s Square: Fundamental for accurate measurements and marking cuts.

•Cutting and Shaping Wood:

•Miter Saw or Circular Saw: For precise cuts on lumber. A miter saw is ideal for repetitive angle cuts.

•Hand Planer: Useful for shaping wood, especially for creating rounded edges or fine-tuning dimensions .

•Orbital Sander: For smoothing wood surfaces after cutting and shaping .

•Working with Cement Board:

•Angle Grinder: Essential for cutting cement board, especially for curves. Be prepared for significant dust and wear appropriate PPE .

•Utility Knife: For scoring and snapping straight cuts on cement board.

•Assembly and Fastening:

•Cordless Drill/Driver: For drilling pilot holes and driving screws.

•Pocket Hole Jig: Highly recommended for strong, concealed joints in wood framing, especially for shelves or internal structures [1, 3].

•Brad Nailer/Pin Nailer: For attaching trim or securing smaller pieces of wood.

•Clamps: Indispensable for holding pieces together while glue dries or fasteners are applied [1, 3].

•Microcement Application:

•Stainless Steel Trowels (various sizes): For applying microcement layers evenly and achieving desired textures [1, 2].

•Finishing Trowel/Squeegee: For smoothing and refining the microcement surface [1, 2].

•Sanding Block with Fine-Grit Sandpaper: For smoothing imperfections after microcement application [1, 2].

•Rollers (short-nap): For applying primers, waterproofing membranes, sealers, and varnishes .

•Safety Gear:

•Safety Glasses, Dust Mask/Respirator, Hearing Protection, Gloves: Always prioritize personal safety, especially when cutting dusty materials like cement board or working with power tools [1, 3].

Gathering all your materials and tools before you begin will streamline the construction process and allow you to focus on the craft rather than making multiple trips to the hardware store. Double-check quantities and ensure all products are compatible with each other, especially within the microcement system.

5. Step-by-Step Construction: Building the Foundation

With your design finalized, materials gathered, and tools at the ready, it’s time to transform your vision into a tangible structure. This section will guide you through the foundational steps of building your custom microcement vanity, focusing on creating a robust and stable frame, followed by the application of the essential substrate and waterproofing layers. Precision and attention to detail in these early stages are critical for the longevity and aesthetic success of your finished vanity.

Step 1: Building the Frame (The Skeleton of Your Vanity)

The frame is the structural backbone of your vanity, providing support for the countertop, sinks, and the microcement finish. The inspiration project utilized a simple yet effective 2×4 construction, demonstrating that robust framing doesn’t need to be overly complex .

Cutting Lumber to Size

Begin by carefully cutting all your lumber (2x4s and any 2x8s or stacked 2x4s) to the precise dimensions determined during your planning phase. Use a miter saw or circular saw for clean, accurate cuts. Double-check each piece against your measurements before cutting to avoid waste. Labeling each piece as you cut it can help streamline the assembly process.

Assembling the Basic 2×4 Frame

For a built-in vanity, the frame will typically consist of a front face frame, side frames (if not built against existing walls), and horizontal supports. The original project describes a frame secured to existing wall studs on the back and right side, with a partial wall on the left .

1.Construct Side Frames: If your vanity is not entirely enclosed by existing walls, start by building the side frames. These typically consist of vertical studs and horizontal rails. Use pocket hole joinery for strong, concealed connections. Ensure these frames are perfectly square.

2.Assemble Front Face Frame: Create the front face frame, which will define the front profile of your vanity. This will include vertical stiles and horizontal rails. If you’re incorporating a 2×8 or stacked 2x4s for a thicker apron, integrate these into the front frame at this stage. The inspiration project used a 2×8 along the front and left side .

3.Connect Frames: Connect the side frames to the front face frame using screws and wood glue. Ensure all connections are strong and the overall structure is plumb and square. Use clamps to hold pieces firmly in place while fasteners are driven.

Securing to Wall Studs and Floor for Stability

This is a critical step for ensuring the vanity is rock-solid and won’t shift or pull away from the wall over time. As previously researched, proper anchoring is paramount .

1.Mark Stud Locations: Transfer the stud locations you marked during planning onto your assembled frame. Pre-drill pilot holes through the frame members that will align with the wall studs.

2.Attach to Wall Studs: Position the frame against the wall. Use long, structural screws (e.g., 3-inch construction screws) to securely fasten the frame directly into the wall studs. Use a level to ensure the frame is perfectly horizontal and vertical as you attach it.

3.Anchor to Floor: For added stability, especially for built-in designs, anchor the bottom plates of your frame to the bathroom floor. Use appropriate fasteners for your subfloor type (e.g., wood screws for wood subfloors, concrete screws for concrete slabs). Again, ensure the frame remains level and plumb during this process. The inspiration project specifically mentions securing the left wall into the floor for stability .

Creating Custom Elements: Partial Walls, Rounded Corners

This is where your vanity truly becomes custom and unique. The inspiration project beautifully demonstrates how to incorporate a partial wall and a rounded edge .

1.Construct Partial Walls: If your design includes partial walls, build these as separate frame sections and integrate them into your main vanity frame. Ensure they are securely attached and plumb.

2.Forming Rounded Edges: For a rounded edge, as seen in the inspiration, you’ll need to shape the wood. The original project used a support block in the corner, traced a round object for the desired curve, and then shaped the wood. This involves:

•Adding a Support Block: Secure a sturdy wood block in the corner where the curve will be. This provides a solid base for shaping.

•Tracing the Curve: Use a large round object (e.g., a bucket lid, a large plate) to trace the desired curve onto the wood. Ensure the curve is smooth and aesthetically pleasing.

•Rough Cuts: Use a jigsaw or band saw to make the initial rough cuts along your traced line. Be careful not to cut too far into the support block.

•Shaping with a Hand Planer: A hand planer is an excellent tool for carving the wood down to the desired curve. Work slowly and deliberately, removing small amounts of material at a time. The inspiration highlights this as an inexpensive and essential tool for woodworkers .

•Smoothing with an Orbital Sander: Once the rough shape is achieved, use an orbital sander with progressively finer grits of sandpaper to smooth out the curve. This will prepare the surface for the cement board and microcement, ensuring a flawless finish .

•Wood Glue is Key: For any custom wood elements, especially those that will be shaped, liberal use of wood glue in conjunction with fasteners (which can be removed after the glue dries for a cleaner look) is essential for a solid bond .

By meticulously constructing the frame and incorporating any custom design elements at this stage, you lay a strong and stable foundation for the subsequent layers of your microcement vanity. This careful preparation will pay dividends in the final quality and durability of your project.

Step 2: Adding the Substrate and Waterproofing (Creating a Durable Shell)

Once the wooden frame is complete and securely installed, the next crucial step is to create a robust, moisture-resistant shell using cement board and a waterproofing membrane. This phase is vital for protecting the underlying wood structure from the bathroom’s inherent humidity and splashes, ensuring the longevity of your microcement finish.

Cutting and Attaching Cement Board to the Frame

Cement board provides an ideal, stable, and water-resistant substrate for microcement. It’s significantly more durable in wet environments than standard drywall.

1.Measure and Cut: Carefully measure each section of the vanity frame that will be covered by cement board. Transfer these measurements to your 1/2-inch cement board. For straight cuts, score the board with a utility knife and snap it. For curved sections, like the rounded edge of a partial wall, use an angle grinder. The inspiration project notes that cutting cement board is a dusty job, so always wear safety glasses and a mask .

2.Attach to Frame: Secure the cut cement board pieces to the wooden frame using cement board screws. These screws are specifically designed to resist corrosion in wet environments and have a head that sits flush with the surface. Space screws every 6-8 inches along the studs and perimeter. Ensure the cement board is flush with the edges of your frame, creating a smooth surface for the microcement.

Constructing Internal Shelves (Pocket Holes)

If your design includes internal shelves, now is the time to integrate them. The inspiration project used 2x4s and pocket holes for shelf construction, a highly effective method for strong, hidden joints .

1.Build Shelf Frames: Cut 2x4s to create the frame for your shelves. Use a pocket hole jig to drill pocket holes at the ends of the horizontal shelf supports. These will be used to attach the shelf frame to the vertical studs of your vanity frame.

2.Install Shelf Frames: Secure the shelf frames into place using pocket hole screws. Ensure they are level and firmly attached. The inspiration also mentions adding an additional 2×4 along the front to make the apron taller, which can be done at this stage to integrate with the shelf structure .

3.Cover with Cement Board: Once the shelf frames are installed, cut and attach 1/2-inch cement board to the top of the shelves, just as you did for the side panels. This creates a continuous, microcement-ready surface.

Taping All Seams with Cement Board Tape

Properly taping the seams is crucial for preventing cracks in the microcement and enhancing the waterproofing system.

1.Apply Tape: Apply fiberglass mesh joint tape (specifically designed for cement board) over all seams where two pieces of cement board meet, as well as where cement board meets any wood framing (e.g., the 2×8 apron) . This tape provides reinforcement and helps bridge any minor movements.

2.Embed in Thin-Set: While the original article doesn’t explicitly state this for the vanity, best practice for cement board seams, especially in wet areas, is to embed the tape in a thin layer of unmodified thin-set mortar. This creates a strong, continuous surface. Allow the thin-set to dry completely.

Applying Waterproofing Membrane (Rubbery Coating, Multiple Coats)

This is the final and most critical step in preparing your vanity for the wet environment of a bathroom. The inspiration project used leftover Elastoshield, but RedGard is another popular and effective option .

1.Clean Surface: Ensure all cement board surfaces are clean, dry, and free of dust or debris before applying the membrane.

2.Apply First Coat: Using a roller or brush, apply a generous, even coat of the liquid waterproofing membrane over all cement board surfaces and any exposed wood that will be part of the vanity structure. Pay particular attention to corners and seams, ensuring full coverage. Allow the first coat to dry completely according to the manufacturer’s instructions (typically 1-2 hours, but can vary).

3.Apply Second (and subsequent) Coats: Once the first coat is dry, apply a second coat, often perpendicular to the first, to ensure complete and uniform coverage. Many manufacturers recommend 2-3 coats for optimal waterproofing, especially in high-moisture areas. The membrane dries to a rubbery, hard finish, creating an impermeable barrier that protects the underlying materials from moisture .

By diligently completing these steps, you will have constructed a sturdy, well-supported, and thoroughly waterproofed foundation for your microcement vanity. This meticulous preparation is the secret to a professional-looking and long-lasting DIY project.

6. Countertop Integration: Seamless or Standalone

The countertop is a focal point of any bathroom vanity, and its integration with your microcement base is a critical design and functional decision. While the inspiration project opted for a high-end, custom-fabricated quartz countertop with integrated sinks, there are several viable alternatives that can align with different budgets and DIY skill levels. This section explores various countertop options and their integration methods, allowing you to choose the best fit for your custom microcement vanity.

Option 1: Integrated Quartz/Stone (The High-End Approach)

The original project chose a Hanstone matte river washed gray quartz in Storm, with integrated sinks, noting the significant cost (over $2k) but also the desired aesthetic . This option offers unparalleled durability, a luxurious feel, and a seamless look, especially with integrated sinks.

•Working with Fabricators: If you choose a custom stone or quartz countertop, you will need to work with a local fabricator. Provide them with precise measurements of your vanity frame and your desired sink type and placement. For integrated sinks, the fabricator will create the sink basins directly within the countertop material, resulting in a sleek, continuous surface. For undermount sinks, they will cut the appropriate opening and polish the edges.

•Installing Before Microcement: The inspiration project wisely installed the quartz counter before applying microcement. This allows for any minor gaps or imperfections between the countertop and the vanity frame to be seamlessly filled and concealed by the microcement application, creating a truly built-in look . Ensure the countertop is perfectly level and securely fastened to the vanity frame using appropriate adhesives or brackets.

•Considerations for Undermount vs. Integrated Sinks: Integrated sinks offer the most seamless aesthetic and easiest cleaning. Undermount sinks provide a clean look but have a visible rim where the sink meets the countertop. Drop-in sinks are the easiest to install but break the continuous line of the countertop.

Option 2: DIY Concrete Countertop (A Cohesive & Budget-Friendly Alternative)

Given the microcement finish of the vanity, a DIY concrete countertop is a natural and aesthetically cohesive alternative. It offers a similar industrial-chic vibe, is highly customizable, and can be significantly more budget-friendly than fabricated stone .

•Building a Form for Pouring Concrete: The first step is to build a sturdy form (mold) for your concrete countertop. This can be made from melamine-faced particle board, which provides a smooth surface and is easy to clean. The form should be built to your exact countertop dimensions, including any sink cutouts. Ensure the form is perfectly level and sealed at the seams to prevent concrete leakage.

•Mixing and Pouring Concrete: Use a high-strength concrete mix specifically designed for countertops, often containing fine aggregates and polymers for increased workability and durability. Follow the manufacturer’s instructions for mixing. Pour the concrete into the form, vibrating it to release air bubbles and ensure a dense, uniform slab. You can embed fiberglass mesh or rebar for added strength, especially around sink cutouts.

•Curing and Finishing Concrete: Once poured, the concrete needs to cure slowly to achieve maximum strength. Cover the form with plastic sheeting to retain moisture for several days to a week. After curing, demold the countertop. You can then grind and polish the surface to your desired smoothness. For a truly integrated look, you can even apply a thin layer of microcement over the concrete countertop before sealing, further enhancing the seamless aesthetic.

•Sealing: Concrete is porous, so a high-quality, food-safe sealer (if applicable) and a durable topcoat are essential to protect it from stains, water, and chemical damage in a bathroom environment.

Option 3: Other DIY Countertops (Butcher Block, Laminate)

For those seeking different aesthetics or even more budget-conscious options, butcher block or laminate countertops can also be integrated with a microcement vanity .

•Butcher Block: This offers a warm, organic contrast to the cool, modern microcement. Butcher block countertops are typically purchased as slabs and cut to size. They are installed by securing them to the vanity frame from underneath. The most critical step for bathroom use is thorough sealing with a waterproof finish (e.g., marine-grade varnish or multiple coats of a penetrating oil) to protect against moisture and humidity. Regular re-sealing will be necessary.

•Laminate: The most economical choice, laminate countertops come in a vast array of patterns and colors, mimicking everything from stone to wood. They are relatively lightweight and easy to cut and install. They are typically secured to the vanity frame with screws from below. While generally water-resistant, special attention must be paid to sealing all exposed edges and seams, especially around the sink cutout, to prevent water infiltration and swelling of the particleboard core.

Regardless of your chosen countertop material, ensure it is securely installed, level, and properly sealed to withstand the demands of a bathroom environment. The choice of countertop can dramatically influence the final look and feel of your custom microcement vanity, so select an option that not only fits your budget but also complements your overall design vision.

7. Mastering Microcement Application: The Art of the Finish

The application of microcement is where the true artistry of this project comes to life. While it may seem daunting at first, with practice and adherence to proper techniques, you can achieve a professional, seamless finish that will be the envy of many. This section will guide you through the step-by-step process of applying microcement, drawing on best practices to ensure a durable and aesthetically pleasing result.

Surface Preparation (Revisited): Ensuring a Pristine Base

Before applying any microcement, a meticulous final surface preparation is paramount. Even though you’ve already installed cement board and waterproofing, this step ensures optimal adhesion and a flawless finish .

1.Cleanliness is Key: Ensure the entire surface of your waterproofed vanity is absolutely clean, dry, and free from any dust, grease, or debris. Use a vacuum cleaner to remove all loose particles, followed by a damp cloth to wipe down the surface. Allow it to dry completely.

2.Smoothness Check: Run your hand over all surfaces. Any bumps, ridges, or imperfections will show through the thin microcement layers. Address these by light sanding or filling with a suitable patching compound, then re-clean.

3.Masking: Carefully mask off any areas you do not want microcement applied to, such as adjacent walls, floors, or the inside of sink cutouts. Use high-quality painter’s tape for crisp lines.

Priming: Enhancing Adhesion

Priming is a critical step that ensures proper adhesion between the substrate and the microcement, preventing delamination and ensuring a long-lasting finish .

1.Choose the Right Primer: Use a primer specifically designed for microcement applications and compatible with your waterproofing membrane. Different substrates (e.g., cement board, existing tiles, wood) may require different types of primers. Consult your microcement system manufacturer’s recommendations.

2.Apply Evenly: Using a short-nap roller or brush, apply a thin, even coat of primer over all surfaces that will receive microcement. Avoid puddling or excessive application. Ensure complete coverage, especially in corners and edges.

3.Allow to Dry: Let the primer dry completely according to the manufacturer’s instructions. This typically takes a few hours, but can vary based on humidity and temperature. The surface should feel slightly tacky but not wet.

Base Coat Application: The Foundation Layer

The base coat is the first layer of microcement, providing a strong foundation and helping to level the surface. It’s often coarser than the finish coat .

1.Mix According to Instructions: Microcement is typically a two-component system (powder and liquid resin). Carefully follow the manufacturer’s mixing ratios and instructions. Mix thoroughly using a drill with a paddle mixer until a homogeneous, lump-free consistency is achieved. Allow the mixture to rest for a few minutes (slake time) before remixing.

2.Apply Thin and Evenly: Using a stainless steel trowel, apply the base coat in thin, even layers. Hold the trowel at a shallow angle (around 30 degrees) to the surface, spreading the material smoothly. Work in small sections, maintaining a wet edge to avoid visible seams. The goal is to achieve uniform coverage, not thickness.

3.Drying Time: Allow the first base coat to dry completely. This can take 4-8 hours, depending on environmental conditions. Once dry, you may apply a second base coat if recommended by the manufacturer or if the surface requires further leveling. Lightly sand any high spots or imperfections between coats with a fine-grit sanding block.

Second Coat Application: Achieving Desired Texture and Color

This is the decorative layer where the final color and texture of your microcement vanity will be established. It requires a bit more finesse and practice .

1.Mix Finish Coat: Prepare the finish coat microcement, incorporating any desired pigments. Again, adhere strictly to the manufacturer’s mixing instructions. The consistency for the finish coat is often finer than the base coat.

2.Trowel Techniques: Apply the second coat (or first finish coat) in thin, overlapping layers. The way you hold and move your trowel will influence the final texture. For a smoother finish, use consistent, sweeping motions with light pressure. For a more textured, variegated look, you can vary your trowel movements and pressure. The inspiration article notes that there’s a learning curve and practice is key .

3.Directional Application: For a uniform appearance, apply the second coat in the opposite direction of the first coat. This helps to eliminate trowel marks and create a more even finish .

4.Smooth and Refine: While the microcement is still wet, use a clean, flexible finishing trowel or squeegee to gently smooth out any ridges or imperfections. This is your opportunity to refine the surface to your desired aesthetic. Work quickly but deliberately.

5.Drying Time: Allow this coat to dry completely, typically 12-24 hours. Depending on the desired depth of color and texture, you may apply a third, even thinner, finish coat. Always allow adequate drying time between layers.

Sanding: Smoothing Imperfections and Enhancing Finish

Sanding after the microcement has dried is crucial for achieving a smooth, refined surface and enhancing the overall aesthetic .

1.Choose the Right Grit: Use a sanding block with fine-grit sandpaper (e.g., 120-220 grit, depending on desired smoothness). For very smooth finishes, you might progress to even finer grits.

2.Gentle and Even Sanding: Gently sand the entire microcement surface in circular motions. Focus on removing any trowel marks, high spots, or minor imperfections. Be careful not to over-sand in one area, as this can create depressions or expose the underlying layer. The inspiration project specifically mentions a concrete sanding stone for tricky corners and edges .

3.Dust Removal: After sanding, thoroughly clean the surface to remove all dust. Use a vacuum with a brush attachment, followed by a tack cloth or a slightly damp cloth. Any remaining dust will compromise the adhesion of the sealer and varnish.

Sealing: Protecting Against Moisture and Stains

Sealing is a critical step that transforms the porous microcement into a water-resistant and stain-proof surface, essential for a bathroom environment .

1.Apply Sealer: Using a short-nap roller or brush, apply the first coat of microcement sealer. Ensure even coverage, avoiding drips or puddles. The sealer penetrates the microcement, filling its pores and intensifying its color .

2.Multiple Coats: Most microcement systems recommend 2-3 coats of sealer for optimal protection. Allow each coat to dry completely according to the manufacturer’s instructions before applying the next. Lightly sand with very fine grit sandpaper (e.g., 400 grit) between coats if recommended, and clean thoroughly.

Finishing Varnish: The Final Protective Layer

The finishing varnish provides the ultimate protection, making the microcement completely waterproof and resistant to household cleaning products .

1.Choose Your Sheen: Varnishes are available in matte, satin, or glossy finishes. Matte is often preferred for a natural, minimalist look, while glossy can enhance color depth and provide a more polished appearance. The inspiration project used a matte sealer over the entire surface .

2.Apply Evenly: Apply 2-3 thin, even coats of the finishing varnish using a clean short-nap roller. Work carefully to avoid streaks or bubbles. Allow each coat to dry completely between applications.

3.Curing Time: The varnish will need a full curing period (often several days to a week) before the vanity can be subjected to heavy use or harsh cleaning. Consult the manufacturer’s guidelines for specific curing times.

Tips for Success: Practice, Thin Layers, Proper Tools, Working in Sections

•Practice Makes Perfect: If you’re new to microcement, practice on a scrap piece of cement board or plywood before tackling your vanity. This will allow you to get a feel for the material and trowel techniques .

•Thin Layers are Key: Always apply microcement in thin, multiple layers rather than one thick coat. This ensures proper curing, reduces cracking, and allows for greater control over the finish.

•Use the Right Tools: Invest in good quality stainless steel trowels and rollers. Clean your tools thoroughly between each step and coat to prevent contamination and ensure smooth application.

•Work in Sections: For larger surfaces, divide the area into manageable sections and work systematically. This helps maintain a wet edge and prevents the microcement from drying prematurely.

•Environmental Conditions: Be mindful of temperature and humidity. High humidity can prolong drying times, while excessive heat can cause the microcement to dry too quickly, making it difficult to work with.

Mastering microcement application is a rewarding process that culminates in a stunning, durable, and unique finish. By following these detailed steps and exercising patience, you will achieve a professional-grade microcement vanity that stands as a testament to your DIY prowess.

8. Final Touches and Maintenance

With the microcement expertly applied, sealed, and varnished, your custom vanity is nearing completion. This final stage involves installing the plumbing fixtures and understanding how to properly care for your new microcement surface to ensure its beauty and longevity. Attention to these details will bring your DIY project to a professional and functional close.

Installing Plumbing Fixtures, Sinks, and Faucets

This step requires careful work to avoid damaging your newly finished microcement surface.

1.Prepare for Installation: Ensure all microcement and varnish layers are fully cured before beginning plumbing installation. Gather all necessary tools and components for your chosen sink(s) and faucet(s).

2.Sink Installation:

•Integrated Sinks: If you opted for integrated sinks within a custom countertop, these are already part of the surface. You will primarily focus on connecting the drain assembly.

•Undermount Sinks: Apply a bead of silicone sealant around the rim of the sink opening on the underside of the countertop. Carefully position the sink and secure it with the manufacturer’s clips or clamps. Wipe away any excess sealant immediately.

•Drop-in Sinks: Apply a bead of sealant around the perimeter of the sink opening on the countertop. Carefully lower the sink into place, ensuring it sits flush. Secure with clips from underneath and wipe away excess sealant.

3.Faucet Installation: Follow the manufacturer’s instructions for your specific faucet. This typically involves inserting the faucet body through the pre-drilled holes in the countertop, securing it from underneath with washers and nuts, and then connecting the hot and cold water supply lines.

4.Drain Assembly: Install the drain assembly for each sink, ensuring all connections are tight and leak-free. Use plumber’s putty or silicone sealant as recommended by the drain manufacturer.

5.Connect P-Trap and Supply Lines: Connect the P-trap to the drain tailpiece and the wall drain. Finally, connect the hot and cold water supply lines from the shut-off valves to the faucet. Turn on the water supply slowly and check all connections for leaks. Address any leaks immediately.

Cleaning and Ongoing Care for Microcement Surfaces

One of the significant advantages of microcement is its ease of maintenance, especially with proper sealing. However, understanding the best practices for cleaning will help preserve its finish for years to come .

•Regular Cleaning: For daily cleaning, simply wipe down the microcement surface with a soft cloth or sponge dampened with water and a mild, pH-neutral cleaner. Avoid abrasive cleaners, scouring pads, or harsh chemicals (like bleach, ammonia, or strong acids) as these can damage the sealer and varnish, compromising the waterproof barrier and potentially discoloring the microcement. The finishing varnish is designed to be resistant to standard cleaning products, but gentle care is always recommended .

•Spill Management: Wipe up spills immediately, especially acidic liquids (e.g., citrus juices, vinegar) or highly pigmented substances (e.g., red wine, coffee), to prevent potential staining, even with a sealed surface.

•Avoid Standing Water: While microcement is waterproof, prolonged exposure to standing water can eventually compromise the sealer. Ensure good ventilation in the bathroom and wipe down any standing water on the vanity surface after use.

•Protective Measures: Consider using soft mats or trays under toiletries and cosmetics to prevent scratches or accidental chemical spills directly on the microcement. Avoid placing extremely hot items directly on the surface without protection.

•Re-sealing (if necessary): Over many years, depending on usage and cleaning habits, the protective varnish layer may show signs of wear. If you notice the surface becoming less water-repellent or showing signs of wear, consult your microcement manufacturer about re-applying a fresh coat of varnish or sealer. This can significantly extend the life and appearance of your vanity.

Troubleshooting Common Issues

Even with careful planning and execution, minor issues can arise. Here are a few common ones and how to address them:

•Cracks: Small hairline cracks can sometimes appear, especially if the substrate was not perfectly stable or if there was significant movement. For minor cracks, specialized microcement repair kits are available. For larger cracks, it might indicate a deeper structural issue that needs professional assessment.

•Discoloration/Stains: If a stain penetrates the sealer, it can be challenging to remove. Prevention is key. For minor discoloration, a gentle scrub with a mild abrasive (like baking soda paste) might help, but always test in an inconspicuous area first. For persistent stains, professional restoration might be required.

•Uneven Finish: If the microcement finish appears uneven, it might be due to inconsistent application or sanding. For minor issues, further fine-grit sanding and re-application of varnish can sometimes improve the appearance. For significant unevenness, more extensive re-application of microcement layers might be necessary.

By diligently caring for your microcement vanity, you will ensure it remains a beautiful and functional centerpiece in your bathroom for many years, reflecting the quality craftsmanship of your DIY efforts.

9. Cost Breakdown and Value Proposition

One of the most compelling reasons to embark on a DIY microcement vanity project is the potential for significant cost savings without compromising on a high-end, custom aesthetic. While the final cost will vary depending on the size of your vanity, your choice of countertop, and material sourcing, a DIY approach can be a fraction of the cost of a store-bought or professionally installed vanity of similar quality. This section provides a detailed cost analysis based on the inspiration project and our research, highlighting the exceptional value proposition of this DIY endeavor.

Detailed Cost Analysis

The inspiration project provides a transparent and encouraging cost breakdown for the basic vanity structure, totaling approximately $180 . Let’s expand on this with a more detailed and generalized cost analysis:

Comparing DIY Cost to Professional Installation/Store-Bought Vanities

The value of this DIY project becomes truly apparent when compared to market alternatives:

•Store-Bought Vanities: A standard double vanity of similar size (55 inches) from a mid-range retailer can easily cost between $1,500 and $3,000, often made from MDF or lower-quality wood. These vanities lack the unique, seamless finish and custom fit of a microcement build.

•Custom Professional Installation: A professionally installed custom microcement vanity would likely start at $4,000 – $7,000 or more, depending on the complexity and location. This includes labor, which is a significant portion of the cost.

•Countertop Costs: The countertop is a major cost variable. The inspiration project’s custom quartz countertop cost over $2,000 . However, a DIY concrete countertop could be achieved for $200-$500 in materials. A butcher block countertop might range from $300-$600, and laminate from $100-$300. By choosing a DIY-friendly countertop, you can keep the total project cost well under $1,000.

The Value of a Custom, High-End Look on a Budget

This project’s true value lies not just in the monetary savings but in the creation of a truly one-of-a-kind, high-end piece that is perfectly tailored to your space and style. The seamless, minimalist aesthetic of microcement is typically associated with luxury architectural designs, and the ability to achieve this look on a DIY budget is a remarkable accomplishment. The satisfaction of building a durable, functional, and beautiful piece of furniture with your own hands is immeasurable. Furthermore, the skills learned in framing, waterproofing, and microcement application are transferable to many other home improvement projects, adding to the overall value of the experience.

By investing your time and effort, you can create a custom microcement vanity that rivals the look of high-end designer pieces for a fraction of the cost, adding significant value and style to your home.

Your Unique Bathroom Transformation

Building a custom microcement vanity is more than just a DIY project; it’s a journey into the world of bespoke design and hands-on craftsmanship. By following the detailed steps outlined in this guide, from meticulous planning and robust framing to the artistic application of microcement, you have the power to create a stunning, durable, and truly unique centerpiece for your bathroom. This project not only offers a cost-effective alternative to expensive store-bought or professionally installed vanities but also provides the immense satisfaction of bringing a high-end, architectural aesthetic into your home through your own efforts. The seamless, minimalist appeal of microcement, combined with its inherent durability and ease of maintenance, makes it an ideal material for the modern bathroom. Embrace the challenge, trust the process, and take pride in the beautiful, functional, and one-of-a-kind microcement vanity you create. Your bathroom will be transformed, and you will have gained invaluable skills and a lasting sense of accomplishment.